Paper Mill Sludge Could be Valuable Raw Material for Clean Fuel Additive

The U.S. Department of Energy's Pacific Northwest National Laboratory (Richland, WA) and the National Renewable Energy Laboratory (NREL) in Golden, CO, working with BioFine Corp., a private company with operations in South Glens Falls, NY, have recently patented a process to produce a fuel additive that makes engines burn cleaner from biomass such as paper mill sludges. The NREL staff has also created a biodegradable herbicide from these waste materials.

Paper mill sludge, containing high percentages of organic waste materials, is currently being incinerated, sent to landfill, or spray irrigated. New processes that would utilize large volumes of this sludge could significantly reduce waste treatment costs in the pulp and paper industry and possibly generate by-product revenue streams at the same time.

Pulp and paper mill sludges are potentially valuable raw materials for conversion into automotive fuel additives that have significant environmental benefits.

At its demonstration center in South Glens Falls, BioFine is converting the pulp and paper mill waste to levulinic acid (4-oxo-pentanoic acid), a chemical "building block" that is normally produced from refined petroleum. The work at BioFine's facilities indicate that levulinic acid can be produced from this kind of biomass at an estimated one-tenth the cost of using petroleum.

Building on the levulinic acid production process developed by BioFine, Pacific Northwest provides a patented catalysis process that upgrades the levulinic acid to produce methyltetrahydrofuran, or MTHF, for use in clean, alternative fuels and chemicals. This process doesn't create harmful pollutants or emit greenhouse gases and requires less energy for production.

The environmental benefits of combining these two processes are so promising and crosscutting to the chemical industry that it received one of five 1999 Presidential Green Chemistry Challenge Awards. "Green Chemistry" is the use of chemistry for pollution prevention and the design of chemical products and processes that reduce negative impacts to human health and the environment.

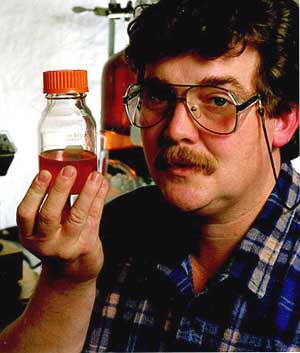

Levulinic acid (4-oxo-pentanoic acid) is a clean intermediary chemical that can be used to create a number of other chemicals. The acid in this photo was created from paper mill sludge. BioFine, is producing levulinic acid at its demonstration plant in South Glens Falls, NY, and DOE's Pacific Northwest National Laboratory is developing a process to turn the acid into an automotive fuel.

MTHF will be used this summer in New York State-owned fleet vehicles as part of a test program. The DOE has approved MTHF as a component in "P-Series" fuels that help achieve government targets for alternative fuels usage. NREL's delta-amino levulinic acid—or DALA—is a broad-spectrum herbicide/pesticide with a projected market of 200–400 million lb/yr.

The partnership between Pacific Northwest, NREL and Biofine, which includes the New York State Energy Research and Development Authority, promises to lead to a full-scale biomass wastes industry that could transform major sectors of the chemical and fuel manufacturing industries in the U.S. and abroad from petroleum-based to renewable feedstocks.

"This is an exciting technology emerging from DOE's investments in biomass conversion, a field where we are literally just touching the surface of the potential for using low-value and waste biomass material for valuable products," said Dennis Stiles, manager of Pacific Northwest's Agriculture and Food Processing Technology programs. "In the near future, we'll be expanding the technology to produce levulinic acid from other organic materials, such as straw left over from grain production, as well as producing a variety of other chemical products, such as solvents, herbicides, and plastics, in addition to MTHF."

The levulinic acid conversion technology that has been demonstrated in Biofine's pilot-scale facility in South Glens Falls is ready for commercialization. A search is underway to site a manufacturing plant in a major pulp and paper producing region, providing the capacity to produce levulinic acid and to upgrade this material to alternative fuels and other products, while reducing the cost of managing the waste sludge."

At its demonstration plant in South Glens Falls, NY, BioFine is producing as much as 1 ton/day of levulinic acid.

By Ken Patrick

The previous article first appeared on Pulp and Paper Online, a sister site to Solid Waste Online within the VerticalNet community.